Common problems, causes and solutions of SPC floor

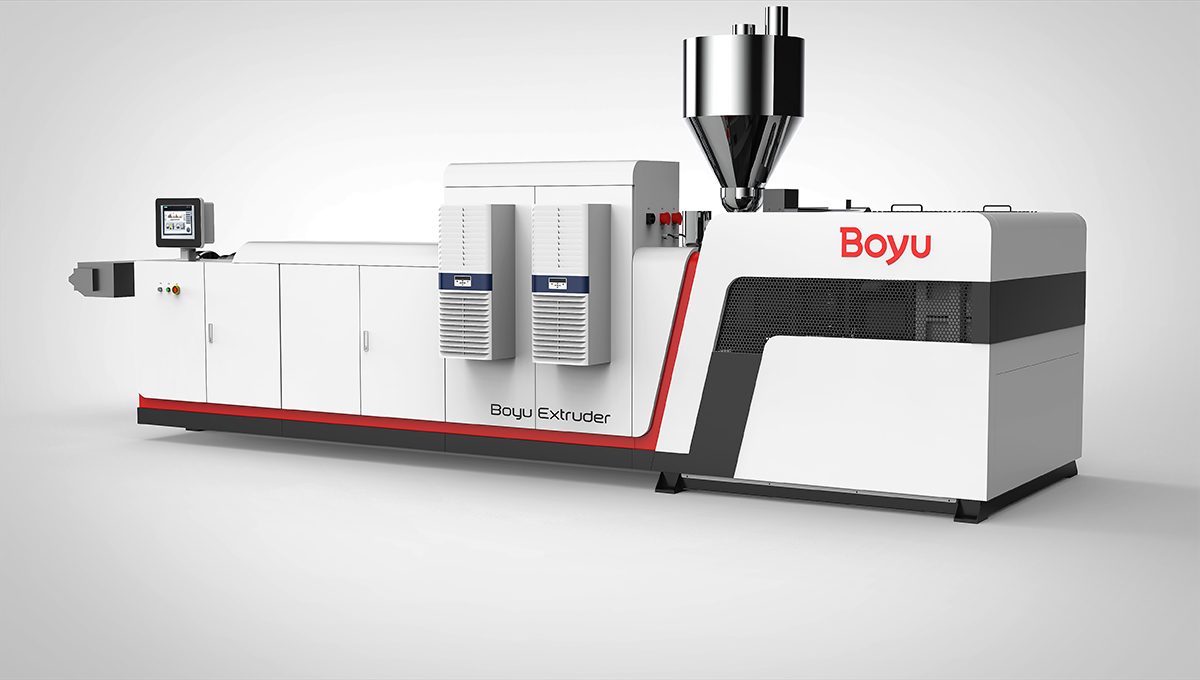

Today, the editor of Boyu introduces the causes and solutions of common problems in SPC flooring. Wuxi Boyu Plastic Machinery Co., Ltd. is the production line of PVC floor extrusion line and the pioneer of SPC floor equipment. The company integrates grille design, production, sales and after-sales service. We are your reliable partner in the plastic machine floor industry, providing high-quality, innovative and efficient extruders for the entire industry. Our equipment is environmentally friendly, and the floor produced by our equipment is formaldehyde-free, heavy-metal-free and recyclable.

1. The product size is unstable, the shaping mold is not full, and the wall thickness is uneven.

Reasons: unreasonable internal and external lubrication of the formula, unstable quantitative feeding speed, serious wear of the screw barrel, and incorrect matching clearance;

Solution: Improve the ratio of internal and external slip agents, correct feeding failures, replace the barrel and screw, and adjust the gap between the barrel and screw.

2. The appearance of the product is uneven, the color deviation is obvious, and the surface has irregular fish scale patterns; the product performance is poor; the toughness is poor, the product is brittle, and the impact resistance is unqualified;

Reason: the formula structure is unreasonable, the inorganic filling is too high, the plasticization is not good, and the amount of impact material is insufficient;

Solution: Modify the formula structure, appropriately reduce the content of inorganic fillers, modify the plasticization of the material to about 65%, and increase impact-resistant materials as appropriate.

3. The output of the finished product is bent, deformed, and partially sags;

Reason: The machine head and the shaping die are not in the same plane, the extrusion speed is too fast, the cold water temperature is too high, the water pressure is too low, the water flow is insufficient, the water and air path is not smooth, and the vacuum negative pressure is insufficient;

Solution: rectify the die and the setting die at the same level, reduce the extrusion speed & cooling water temperature, increase the water pressure and flow, adjust the vacuum negative pressure to check the smooth flow of the water and air paths.