Analysis of Plasticization Mechanism in Each Zone of Twin Screw Extruder for PVC Products

Analysis of Plasticization Mechanism in Each Zone of Twin Screw Extruder for PVC Products

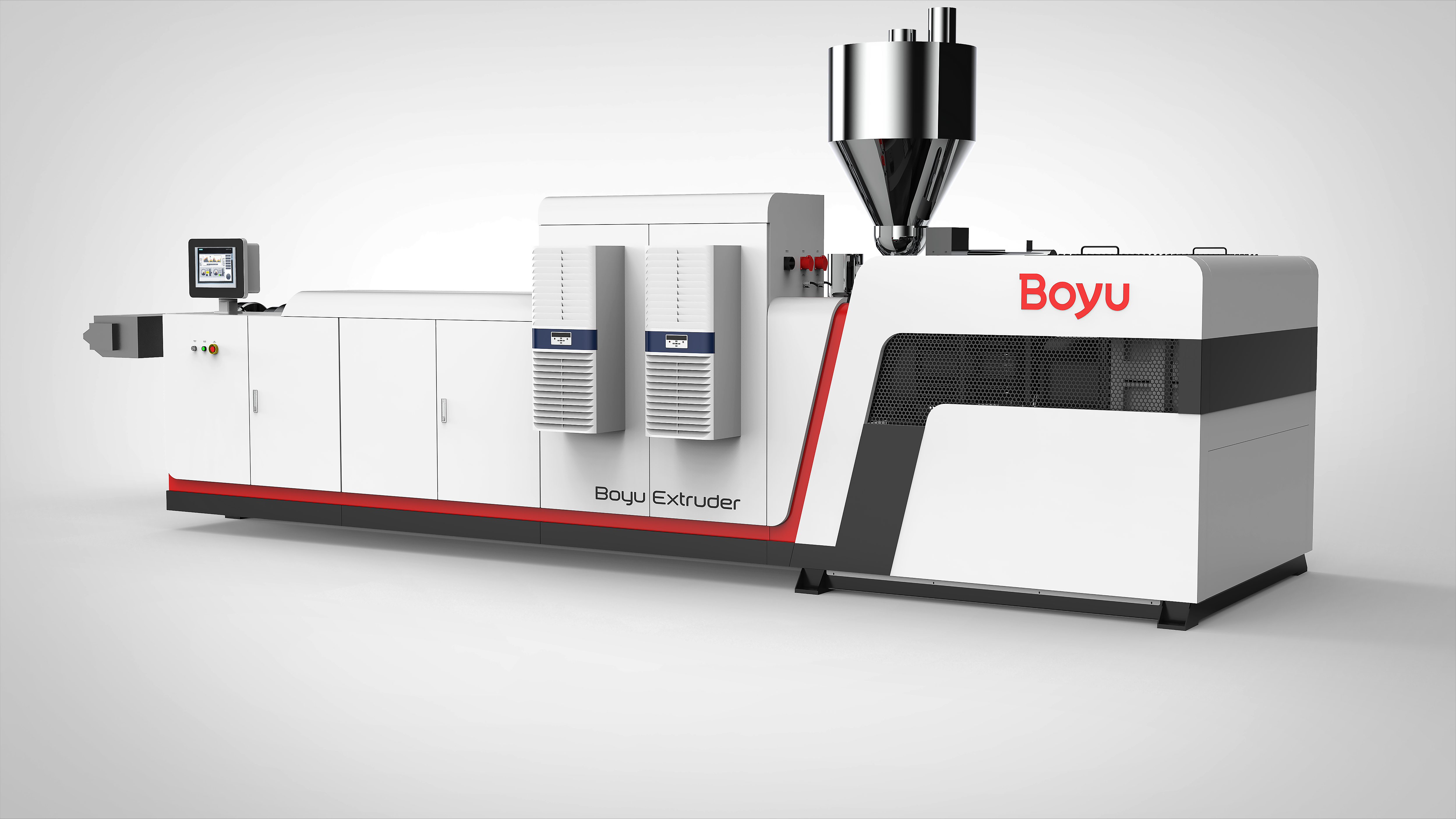

Conical Twin-screw Extruder

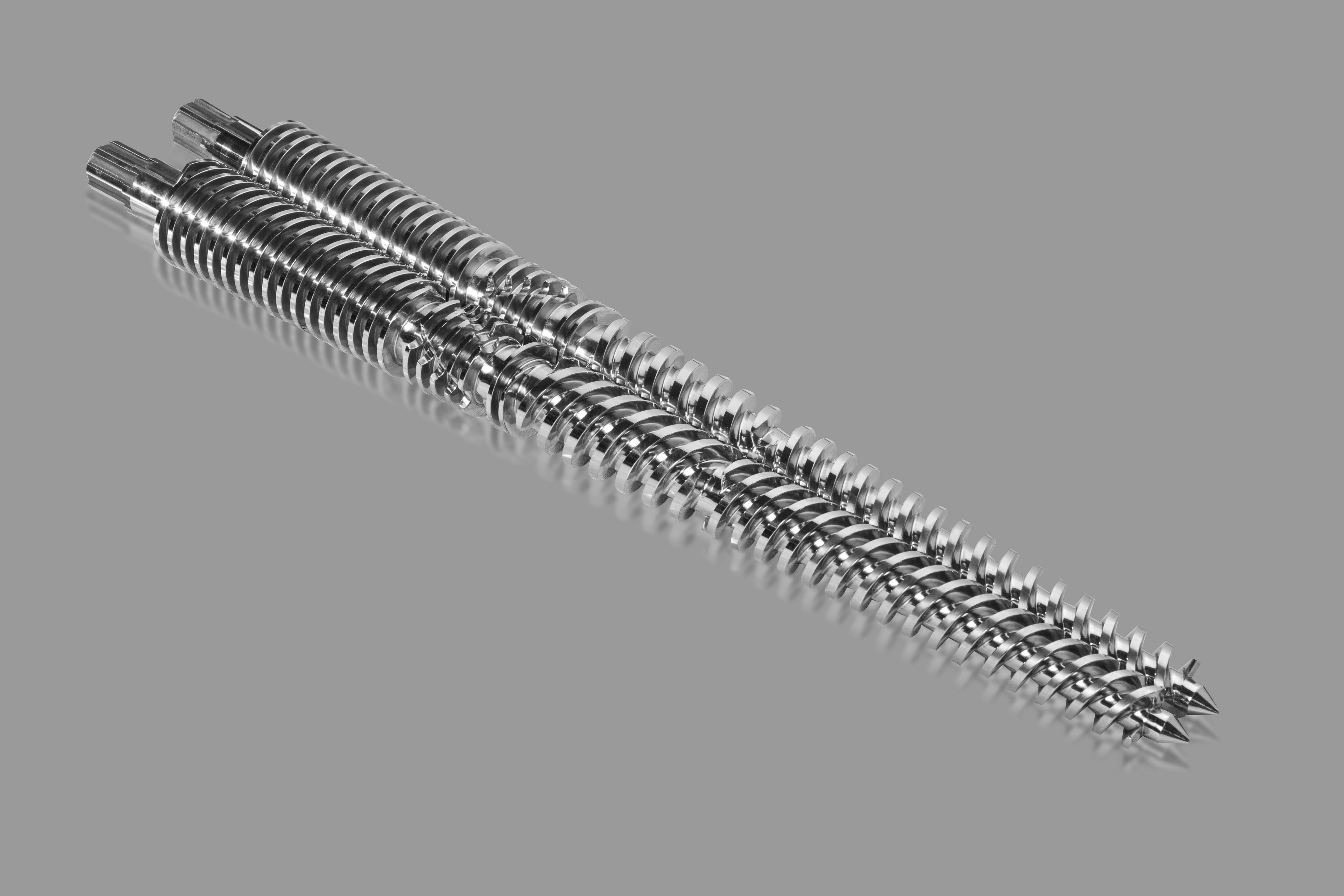

1、 Mechanism of plasticization in solid conveying zone

In the barrel, the solid polymer (PVC) and its auxiliary agent flow, preheat, compaction area is defined as the solid conveying area. First of all, the flow of solid polymer particles in the hopper into the barrel is realized by gravity. While advancing in the direction of the machine head, the particles in the hopper flow continuously. In the solid conveying area (barrel C1 area), the particles such as macromolecules and small molecules in the PVC material are gradually heated, and at the same time, the shearing action of the screw and the friction between the particles also increase the heat of the particles, so that the particles can fully contact, diffuse and penetrate in a dense state.

In this area, due to changes in screw pitch, flight width, etc., the PVC material particles are densely compacted to form a solid bed or solid plug that slides on the screw groove. The solid plug movement depends on the friction between the barrel surface and the solid plug, while the friction between the screw and the solid plug prevents the solid plug from moving. Therefore, in the barrel, the PVC material particles do not advance in the same direction, but roll and slip from time to time, rotate with the screw, "bridge", pile up behind the "bridge", break through the "bridge", and the process is repeated as the PVC material is extruded and the PVC material flows within the hopper.

In this area, the extrusion plasticization quality of PVC material is better. In terms of state, PVC is transformed from glass state to high elastic state; in terms of aggregate structure, 50% to 60% of PVC resin particles are broken and changed to primary state. The surfaces of the particles and the various auxiliary particles are fully contacted and diffused with the primary particles.

It is worth pointing out that for stable operation, the height of the solid material in the hopper must be above a certain critical value at all times. Above this critical value, the change of the material surface height will not affect the performance of the extruder, but if the material surface height is lower than the critical value, it becomes a strong unstable factor. The change of the height of the solid material will cause the change of the bottom pressure, which will change the operation of the extruder, resulting in the deterioration of the extrusion and plasticization quality of the PVC material.

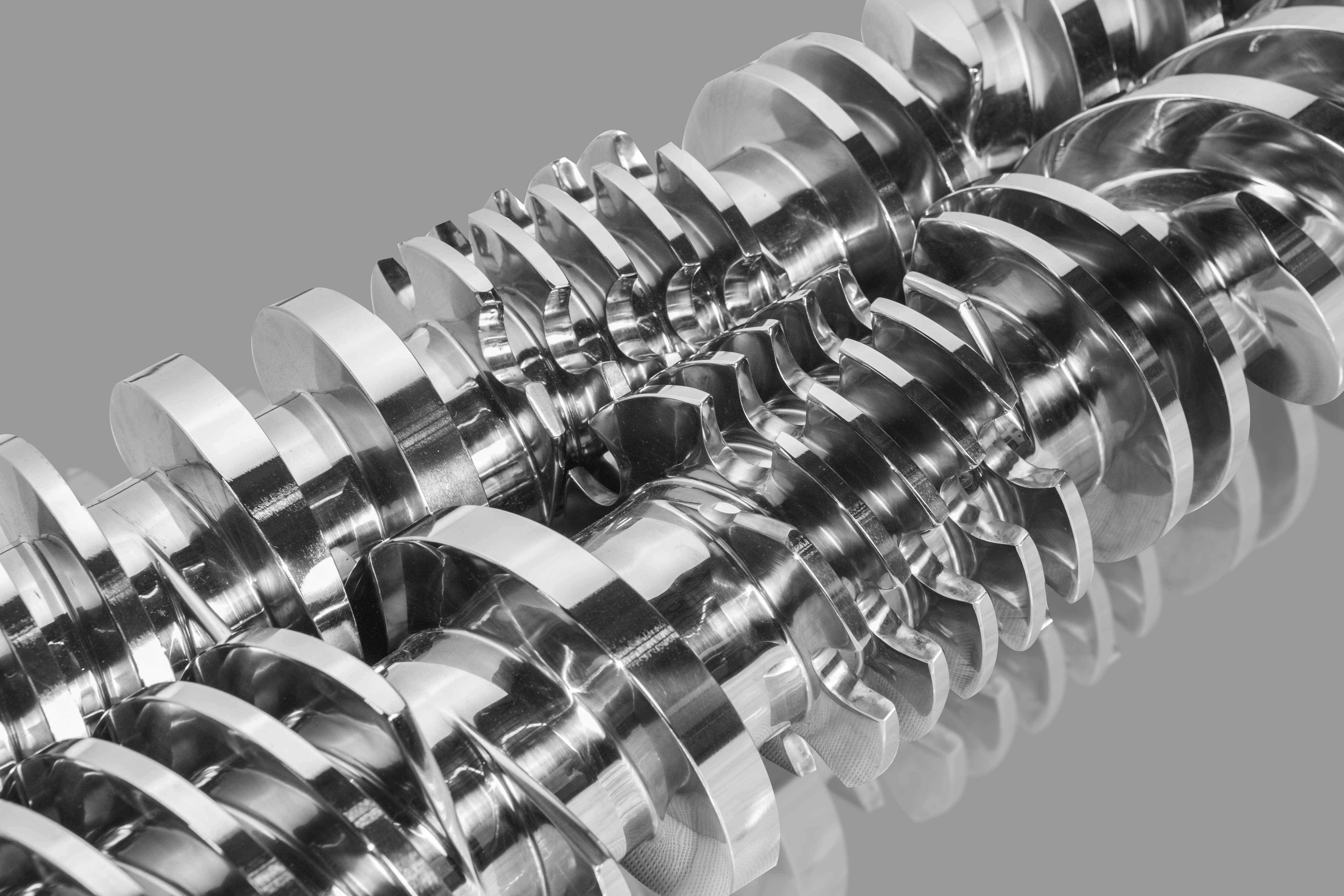

2、Melting zone plasticizing mechanism

In the barrel, the coexistence region of the solid polymer and the melt is defined as the melting zone or the phase transition zone. This zone is the C2, C3 heating zone. The melting zone is the main part of the extruder, especially the temperature setting (barrel C2 zone, C3 zone, screw core) and screw speed setting, screw-screw clearance, screw-barrel clearance, etc. The extrusion quality of PVC material has an important impact. When the PVC material reaches the melting zone, due to the change of the screw pitch and the width of the screw, the PVC material particles have already generated considerable pressure while being compacted. These pressures and the softening effect of the surrounding heat medium together, Turn the compacted particles into a dense "solid bed". The solid bed at this time is a mixed state composed of a part of PVC high elastic state, a part of PVC glass state, and a small amount of PVC viscous flow state. The solid bed has the shape of a helical channel and slides within the channel. Due to this relative motion, a velocity distribution is created in the melt film between the solid bed and the barrel surface. As a result, the melt in the melt film begins to flow toward the thread, and when it encounters the flight, the flight "scrapes" the melt off the barrel and collects in the back of the groove in front of the advancing thread. in the molten pool. As the solid bed moves along the channel, more and more molten material is brought into the molten pool, so the size of the molten pool increases while the size of the solid bed decreases. The solid bed is gradually destroyed and transported forward in a viscous flow state.

In this area, the extrusion plasticization quality of PVC materials is better. From the perspective of state, PVC is transformed from a high elastic state to a viscous flow state; from the perspective of the aggregated state, the primary particles of 60-70% PVC are broken and changed to first-level. Particles, various auxiliary molecules contact with PVC first-level particles to form a physical and chemical combination.

In the melting zone, the factors that improve the extrusion and plasticization quality of PVC materials are:

(1) Increase the screw speed

(2) Increase the set temperature of the barrel in the melting zone

(3) Appropriate screw and barrel clearance

There should be an optimal set of melt zone barrel temperatures for a particular PVC profile production formulation.

3、 Mechanism of plasticization in the melt transfer zone

In the barrel, the solid polymer is completely converted into a melt, and the part where the melt is forced to be delivered to the head is defined as the melt delivery zone (barrel C4 heating zone). In this area, the melt is further reacted and homogenized. With the continuous quantitative extrusion of the viscous fluid of the PVC material, the melt pressure is formed to ensure the compactness of the final molded product of the PVC material. In this area, the PVC material with better extrusion plasticizing quality still maintains the viscous flow state of PVC macromolecules. From the aggregated structure, it is a crystal composed of PVC first-level particles and a small amount of primary particles. This part of the primary Particles can increase the strength and toughness of the final material. When the material containing this crystalline material is extruded and cooled, under the action of external force, the primary particles can hinder the movement of the first-order particles and improve the strength; and due to the large surface area of the primary particles, they can absorb part of the impact energy and improve the toughness when they are impacted.