Extruder Screw Introductory knowledge

The role of the extruder screw is to make the rubber material with the screw rotation movement gradually into linear movement, to the direction of the head, and with the fuselage, compression heat, softening mixing, mixing of rubber material.

1

基本知识

1 Basic knowledge

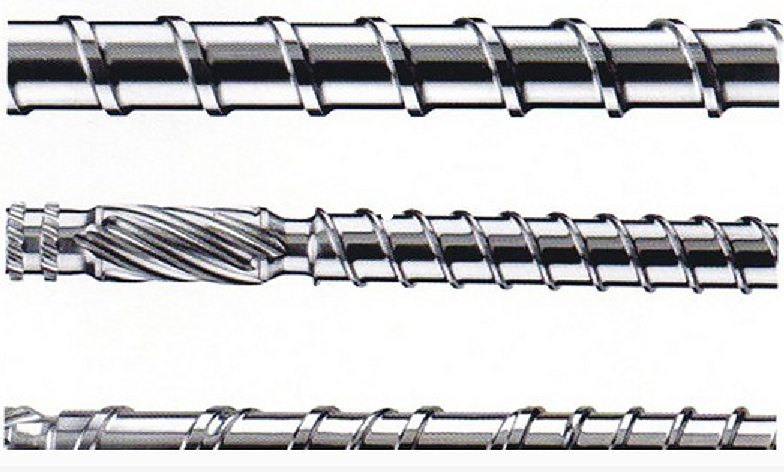

A screw consists of a thread and a cylinder. The screw has a long hole along the center line for cooling water. The tail of the screw is arranged in the thrust bearing to avoid the adverse force when squeezing the rubber to push the screw.

The diameter of the screw is slightly smaller than the inner diameter of the steel sleeve of the fuselage, that is, the diameter of the screw and the inner surface of the steel sleeve to have a gap, the gap is generally controlled in the diameter of the screw 0.002~0.004 times. Clearance is too small will cause the screw "sweep chamber", wear, and even the phenomenon of stuck screw; The gap is too large rubber material backflow affect the amount of extrusion, low production efficiency, but also affect the product quality.

2 Characteristics of screw threads

Thread depth has a direct relationship with the production capacity of the equipment, the thread depth is large, under a certain pressure, extrusion rubber material. But plasticizing is difficult and screw strength is poor. Screw thread depth is generally controlled at 0.18~0.25 times of screw diameter. The thrust surface of the thread should be perpendicular to the axis of the screw, and the opposite side of the thrust surface should have a certain slope. The axial distance of adjacent threads is called pitch, and the screw of rubber extruder is usually double threaded screw with equal distance and unequal depth. The volume between pitches is calculated as follows: tgФ=L/πD

F=h(πD tgФ-e):Ф——The slope of the screw propulsion surface relative to the surface

L——Space distance

D——Screw diameter

e——Thread peak width

F——Volume between pitches

Thread peak width is generally 0.07~0.1 times the diameter of the screw, in which the screw of the small specification extrusion rubber machine can be larger, and the screw of the large specification extrusion rubber machine can be smaller, the peak width of the thread can not be too small, too small peak strength is too small; Too much will reduce thread volume. Affect the yield, and cause the glue burning due to friction heat. The thread distance is usually equal to or slightly greater than the screw diameter.

The head of the screw has three shapes: flat, semicircular and conical. Conical screw is commonly used.

3

螺3.杆的长径比

3 Length-diameter ratio

The length-diameter ratio of screw is the ratio of screw length L to screw diameter D. The screw length-diameter ratio is large, that is, the screw working part is long, the plastic material is good, the mixture is uniform, the rubber material is under pressure, and the product quality is good. However, the long screw is easy to cause coke, screw processing is difficult, increase the extrusion power. The screw used for hot feeding extruder generally takes 4~6 times the length-diameter ratio, and the screw used for cold feeding extruder generally takes 8~12 times the length-diameter ratio.螺杆的压缩比

4 Compression ratio of screw

The ratio of the volume of the first pitch at the feed end of the screw to the volume of the last pitch at the discharge end is called the screw compression ratio. The calculation formula of compression ratio is as follows:

(S1-e)(D-h1)h1

I = —————————

(S2-e)(D-h2)h2

S1——First pitch of feed end of screw mm

S2——The last pitch of the discharge end of the screw mm

h1——Depth of groove at feed end of screw mm

h2——Depth of screw groove at discharging end of screw mm

D——Screw diameter mm

e——Thread peak width mm

Screw compression ratios can be obtained in the following ways:

1、 Pitch changes, groove depth unchanged;

2、 Screw groove depth change, pitch unchanged;

3、 Pitch and groove depth both changed

Wire and cable factories mostly use isometric and unequal depth screw. The calculation formula of compression ratio is as follows:

I = h1/h2

The size of compression ratio has a great impact on the quality of the product, the compression ratio is large, the tightness of the rubber material is high, the surface is smooth. If the compression ratio is too large, the reaction of the rubber material to the screw is also large, and the screw is easy to be broken. The screw compression ratio of squeezer is generally controlled from 1.3:1 to 1.6:1.

Another type of screw is the separation screw. This kind of screw is to add an additional thread to the middle of the screw. Screw is divided into three sections: feeding section, melting section, metering section. The middle part of the additional thread is the molten section, the feeding section refers to the starting point of the screw feed to the additional thread, and the metering section refers to the end point of the screw head to the additional thread.

5 Material of the screw

The screw must be resistant to heat, wear and abrasion. Therefore, heat treatment should be carried out when processing the screw, chromium plating or nitriding surface. The commonly used materials are 45# steel or chromium molybdenum aluminum alloy steel.

Sections

Material movement in extruder screw is divided into three sections, so the design of screw is often carried out in sections. Because each section is a continuous channel, so in actual production, as long as it can meet the requirements, it is not necessary to divide the screw into three sections, in fact, some screw only two sections, and some are not segmented. For example, when extrusion nylon this kind of crystalline material, only feeding section and homogenization section, general screw extrusion soft PVC plastic screw, can use all the compression section, and do not have to be divided into feeding section and homogenization section.

The piecewise form of the screw is obtained from experience and mainly depends on the nature of the material. Feeding length can be from 0 to 75% of the whole length of the screw, generally speaking, the longest extrusion crystalline polymer, hard amorphous polymer, soft amorphous polymer is the shortest. The length of the compression section usually accounts for 50% of the total length of the screw, except of course for nylon and PVC plastics mentioned above. When extruding PE, the length of homogenizing section is 20-25% of the whole length. But for some heat-sensitive materials (such as POLYvinyl chloride), the material should not stay too long in this section, you can not homogenize the section. Some high-speed extruders even take 50% of the length of homogenization section.

Compression Ratio

The extruder compression ratio required for various plastics is not fixed and can have a range. Different raw materials require different compression ratios. For example, when extruding soft polyvinyl chloride plastic, if it is granular material, the screw compression ratio is usually 2.5-3, if it is powder mixture, the compression ratio is 4 ~ 5. Selection of screw compression ratio.

The compression ratio can be obtained in the following ways:

(1) Pitch change (equal depth and unequal distance). The advantage of this structure is that the relatively large compression does not affect the strength of the screw, the disadvantage is that the screw processing is difficult, close to the end of the screw screw Angle is too small to make the material flow can not be smooth, easy to produce nest material.

(2) Screw groove depth changes (isometric and unequal depth). Its advantages are easy to manufacture, large contact area between material and barrel, and good heat transfer effect. The disadvantage is that the strength is weakened, and special attention should be paid to the use of long screw and large compression ratio.

(3) Pitch and groove depth are changed (unequal distance and depth). If properly designed, the screw can achieve maximum advantages and minimum disadvantages. In the actual production mainly from the processing and manufacturing convenience, isometric and unequal deep screw application.

The length to diameter ratio L/D

Plastic extruder extrusion molding with more varieties of plastic, a screw can not be all plastic. The screw should be designed according to the characteristics of raw materials and considering the commonness of various raw materials as far as possible, so that a screw can extrude several plastics at the same time, which is of economic significance in industrial production. The reverse thread at the back end of the screw prevents material leakage.

Screw length-diameter ratio L/D, screw diameter D refers to the outer diameter of screw thread. Effective screw length L indicates the working length of the screw, as shown in Figure 3-14. Effective length and screw length are different. The aspect ratio is the ratio of the effective length of the screw to its diameter. In the early stage, a long diameter of the screw is relatively small, only 12-16. With the development of plastic molding industry, the length-diameter ratio of extruder screw increases gradually, currently commonly used for 15, 20, 25, up to 43.

Increasing the aspect ratio has the following benefits,

1.The physical and mechanical properties of the products can be improved with sufficient screw pressure.

2.Good material plasticization, good product appearance quality.

3.Extrusion capacity increased by 20-40%. At the same time, the screw characteristic curve with larger aspect ratio has smaller slope, flatter and stable extrusion quantity.

4.Conducive to powder forming, such as PVC powder extrusion tube.

But the increase of aspect ratio makes it difficult to manufacture screw and assemble screw and barrel. Therefore, the aspect ratio cannot be increased indefinitely.