The reason and the solution of the material escaping from the extruder vacuum port

In the extrusion process, it is necessary to exhaust gas from the molten material. If these gases cannot be discharged, there may be pores, bubbles and surface dimness and other defects on the surface or inside the product, and the seriously defects even affect the physical, mechanical, chemical and electrical properties of the product. 1~2 exhaust ports are arranged between the feeding port and the machine head to remove the moisture and other volatiles in the molten extruded material. But the opening of the barrel often appears some problems, the most common problem is material escaping from the exhaust port. A small amount of material will affect the volatile discharge, which affecting the quality of the product; A large amount of material will block the exhaust port, and even cause a shutdown.

There are two reasons for material escaping generally. One is that the screw design is unreasonable, which lead to the material flow back at the exhaust port; and the other is the design of the exhaust port is unreasonable, and the molten material is "caught" when it passes through the exhaust port. Find the reason first from the exhaust port to see whether the material in the screw flow back. In most of the exhaust type extruders, you can see the melt rotating forward movement in the screw. In generally, the screw groove is filled with the material not more than 50%, if more than, not only affect the exhaust effect, but also may cause exhaust port escapes material; When less than 50%, the screw can work normally. Material escaping may be caused by improper exhaust port or shunt element design.

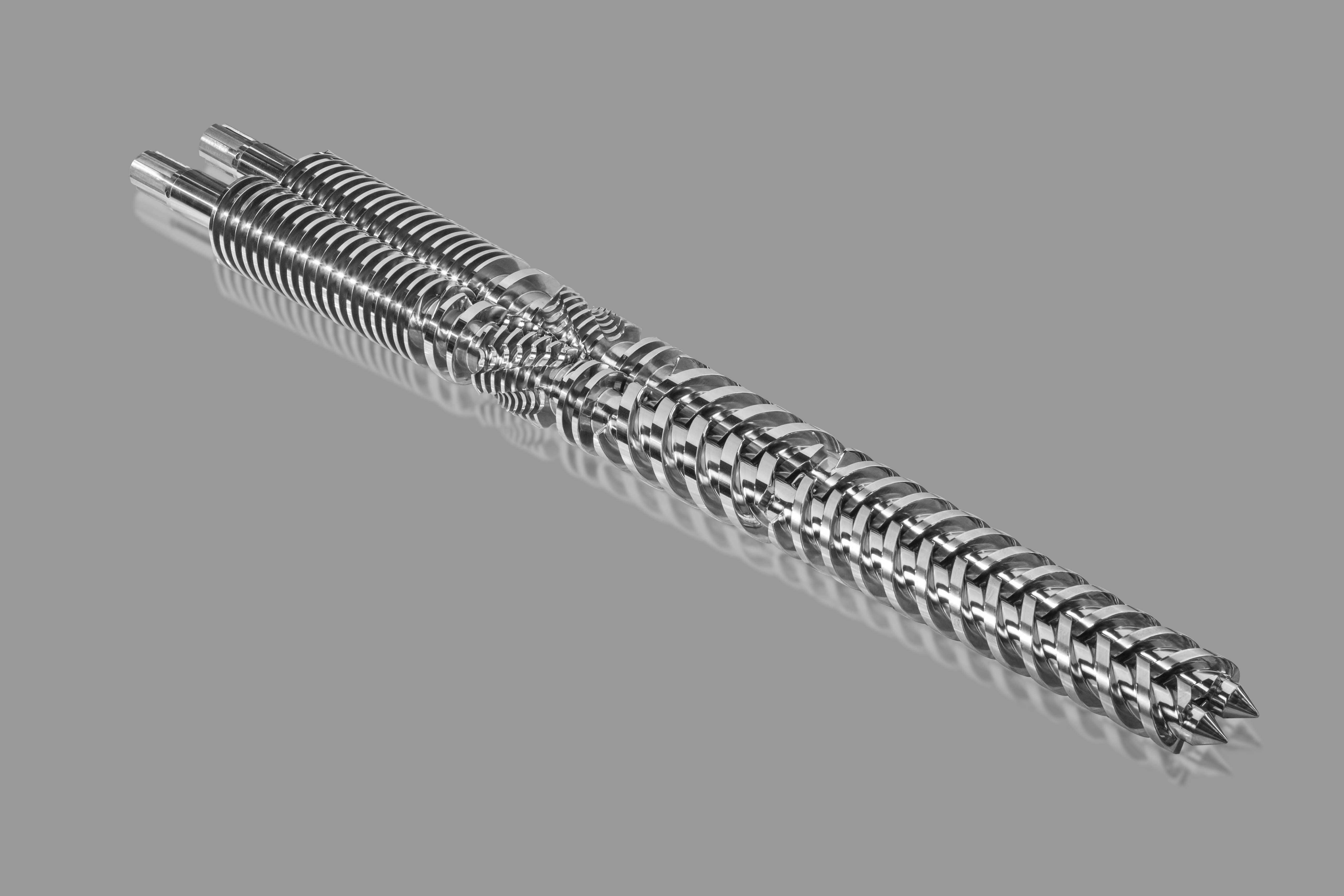

1. The screw element

Exhaust screw adopts multi-stage design, the advantage of this design is that the exhaust port under the conventional pressure, which will not lead to the material flow out. Extruders with one exhaust port require 2 steps screw, and extruders with two exhaust ports require 3 steps screw. Each step has conventional pressure section, compression section and metering section. The first initial step is conventional pressure feeding section, and the second step is conventional pressure exhaust section, which is the location of the exhaust port. There are two main problems in the design of the screw of the exhaust extruder. First, when reaching the exhaust section, the material must be completely melted to discharge the volatile material. Second, the feeding volume of the second stage screw must be greater than that of the first stage screw, so that the screw groove at the beginning of the second stage is not full, so that the exhaust port can be maintained at normal pressure. When the feeding volume of the first stage screw is greater than that of the second stage screw, the melt in the extruder will flow back. To solve this problem, it is necessary to reduce the first stage feeding volume or increase the second stage feeding volume.

2. The process conditions

The easiest and quickest way to solve the material escaping is to change the processing conditions. For example, reducing the temperature, increasing the friction and shear stress along the barrel or screw and increasing the friction or viscosity along the surface of the barrel to increase the feeding volume.

The following methods can be used to reduce the first stage feeding volume: (1) Increase the temperature of the barrel in section 2 and section 3. (2) Cooling the first stage screw. (3) Feeding with the starvation method. (4) Adjust the temperature of the feeding hopper (repeated experiments are needed).

The following methods can be used to increase the second stage feeding volume: (1) Reduce the barrel temperature of the second stage. (2) Increase the screw temperature of the second stage. (3) Raise the head temperature. (4) Increase the head interval or reduce the head resistance. (5) Reduce the number of filters. (6) Use the filters with a larger gap.

Other methods will be used if changing the processing conditions can not solve the problem, such as redesigning the screw to reduce the head resistance; lengthening the screw and barrel or installing a gear pump between the extruder and the head. The installation of gear pump can solve the problem of material escaping, but it is more expensive than new screw.

3.Exhaust Port

The design of the exhaust port has some problems if the screw at the exhaust port is only partially filled but the exhaust port is still escaping material. The exhaust port should be wider than the rolling material stream to ensure that the exhaust port are not blocked by melt. At the same time, the opening of the exhaust port should not be too large to reduce the melt residence time and the expansion time of the material stream. In normal operation, the screw groove is half full, then the exhaust port is normal pressure, in fact, there is still pressure in the rolling melt, the pressure is about 0.21 ~ 0.35Mpa or higher, enough to make the melt at the exhaust port expand. The normal viscoelastic expansion of the material should be in consideration in the designing of the exhaust port, otherwise part of the rolling melt stream will be "caught" and deposited at the shunt element. The amount of expansion of the melt stream is determined by the time it takes to pass through the exhaust port. A longer residence time with a greater expansion. Residence time is controlled by the screw speed and the size of the exhaust port. Increase the screw speed can reduce the residence time. This is the reason why low speed extrusion is more serious material escaping than high speed extrusion. However, the greater exhaust port opening with a longer residence time. The exhaust port will be blocked when the melt builds up at the exhaust port. The solution is to change the opening of the exhaust port to allow the melt to expand normally at the exhaust port. If the rolling melt stream expands by 5 ~ 10mm, the opening depth of the exhaust port should be at least 5 ~ 10mm.

4. The shunt element of the exhaust port

For a real example, a 150mm freshly polished single-screw extruder with a exhaust port is unable to produce a qualified product due to serious material escaping when extruding sheet material. The operator wants to check the melting material in the screw groove at the exhaust port, but it is impossible to see the screw, which indicates that there is a big problem in the design of the shunt element, and the operator has to take down the shunt element to check the full degree of the screw groove. After inspection, it was found that the screw groove was filled with only 40%, which indicates that the screw design was reasonable.

And then the focus of the failure is on the shunt element. There is a serious defect in the design of the shunt element, although this is a famous extruder manufacturer. Upon inspection of the shunt element, it was found that the exhaust port was not only provided with a bottom cut at the upper stage to allow the material to expand normally, but also at the lower stage. The bottom cut of the upper screw is completely unnecessary and is highly undesirable because it increases the residence time of the molten pool at the exhaust port and causes the molten pool to expand more, increasing the melt pressure accumulation at the exhaust port. Another problem is flat and rectangular exhaust port, which are more difficult to clean than the straight exhaust port. If the shunt element is properly designed, the exhaust port should be perpendicular to the radius of the barrel. Based on the above analysis, the shunt element can be repaired in the following two ways: first, the upper bottom cut is filled with metal; Second, the rectangular opening is changed to radial so that the operator can see the melt in the screw. Through the improvement of the above method, the problem of material escaping is solved and the high quality products are produced.

Conclusion

Exhaust screw whether escaping material is directly related to extrusion process, plastic property, screw and exhaust port design, so the manufacturers should understand well to the processing technology, resin characteristics, and the equipment performance in order to make the exhaust extruder running normal and stable when using the exhaust extruder for production and processing.